The last few years have seen significant progress in the development of technology to weigh pigs in a more labour-efficient way.

Now the challenge is to understand how we use and get as much value out of this data as we possibly can, as it could be worth many pounds per tonne of feed costs saved and/or revenue earned at slaughter.

In an attempt to address this, John Richardson, of Pig Production Services, and Mick Hazzledine, of Premier Nutrition, outlined the complexities around weight variation and the value of managing this on-farm. Mr Richardson said: “Pigs aren’t like the proverbial ‘peas in a pod’ – they can have a 2 to 2.5-fold spread of weights at entry to finishing and up to a 2-fold spread at first draw. This is a dilemma for nutritionists but also for producers.”

He explained the true value of managing this variation: “There can be a 3-fold difference in margin per pig place between first draw and the last 30% of pigs sold. The aim must be to better manage variation by targeting these lighter and slower growing pigs to improve overall performance of the batch.”

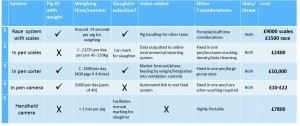

There are a number of different technology options that enable real time daily growth monitoring to aid better forecasting of the delivery weights and early detection of problems. The technology can also help producers and nutritionists optimise feed programmes to help reduce nutrient excess and nitrogen (N) and phosphorus excretion.

Mr Hazzledine outlined the additional value of combining weight with feed data from a nutritionist’s point of view, given that most nutritionists use growth models to determine feed specifications and feeding programmes.

The models are informed by on-farm data, such as daily liveweight gain and feed intake information to help produce nutrition, feeding and selection strategies so that, perhaps, 85% of the population are growing to their maximum potential.

He said that using technology to understand more precisely the feed curves for a farm allows these models to go a step further and become much more farm-specific, identifying irregularities in the growth curve and testing interventions. “We could more accurately supply nutrients to the pigs and better evaluate the benefits of approaches such as three-feed finishing, feed blending and split-sex feeding.

“Feed blending capabilities are particularly useful, as nutritional interventions can be made very quickly, rather than possibly waiting for a bin to run out. We could also more accurately reduce N excretion and soya usage. A reduction in digestible lysine of 0.1% could reduce feed costs by about £8/t.”

A poll of the audience estimated the value of having this real time growth and FCR data as £3 per pig. But on one unit AHDB visited, using this regular weight data has allowed the producer to generate even more value by exploiting heavier slaughter weights with the confidence of having no overweights – so much so that the farmer has added 5kg to his average slaughter weight.