Chris Fogden is a first-generation farmer and Nuffield Scholar, who owns and manages 950 outdoor sows on 40ha of rented land within the rotation of a large Norfolk arable estate

Four or so years ago I was approached about breeding and finishing a few pigs for a niche market, mostly abroad. I believe that we in the outdoor job are not exploiting what we do fully – we are over-producing for any real premium market at home and there are huge opportunities in markets abroad that don’t have the climate to breed pigs outdoors.

So my ears pricked up. The target market was to be the Far East, particularly Japan, where there was a market paying a massive premium for the piggy equivalent of Kobe or Wagyu beef with its large amount of intramuscular fat giving rise to excellent flavour and texture.

The pork equivalent is called Kurobuta and is from pure-bred Berkshire pigs. Our brave experiment was to use Berkshire as a terminal sire over our commercial outdoor sows, then see what happens. I needed assurance that I wouldn’t be left high and dry, with some unmarketable pigs if nobody would buy the result. A fixed price would be paid and we shook on it.

So, having procured a regular supply of pedigree Berkshire semen from Deerpark, in Northern Ireland, we aimed to produce 50 piglets per week. Three months, three weeks and three days later the first pretty- coloured piglets were born and we rather fell for them. They were tough as old boots, perfect for their basic farrowing accommodation.

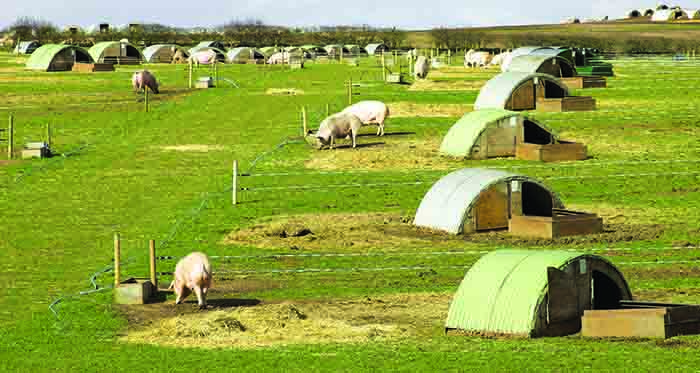

We grew and finished them in second-hand weaner tents and runs, housing them in the same tent from weaning right through. When a field away from the sows was available it was drilled with grass and the tents were gradually relocated. A slight drawback was that my landlord took a distinct dislike to the white tents.

Surprisingly, with their ‘unimproved’ parentage, the pigs grew like mushrooms, despite a growth curve that went very flat after about 70kg liveweight. They grew at about 720g per day from 8kg to 100kg, without any antibiotics or zinc oxide.

I was invited to join the processor and his team to taste the first pig killed. I have never tasted anything so good. They were a little bit disappointed at the backfat, which could be measured in inches, and I struggled with sorting finished pigs.

In the end, the export markets didn’t materialise and nobody at home would pay what we needed. So, suffice to say, the last finished pigs went in March. The processor honoured his handshake, the tents are now rented out to a neighbour and my landlord is happier.