Earlier this year, Shedden Farms in Shipton, North Yorkshire, participated in an unprecedented environmental baseline assessment, spanning 685 farms across 238,000ha of UK farmland.

Hugh Shedden, a Nuffield scholar and second-generation pig farmer, has spent the past five years improving his farm business to drive feed efficiency, enhance production and build resilience, starting with a business model shift in 2019.

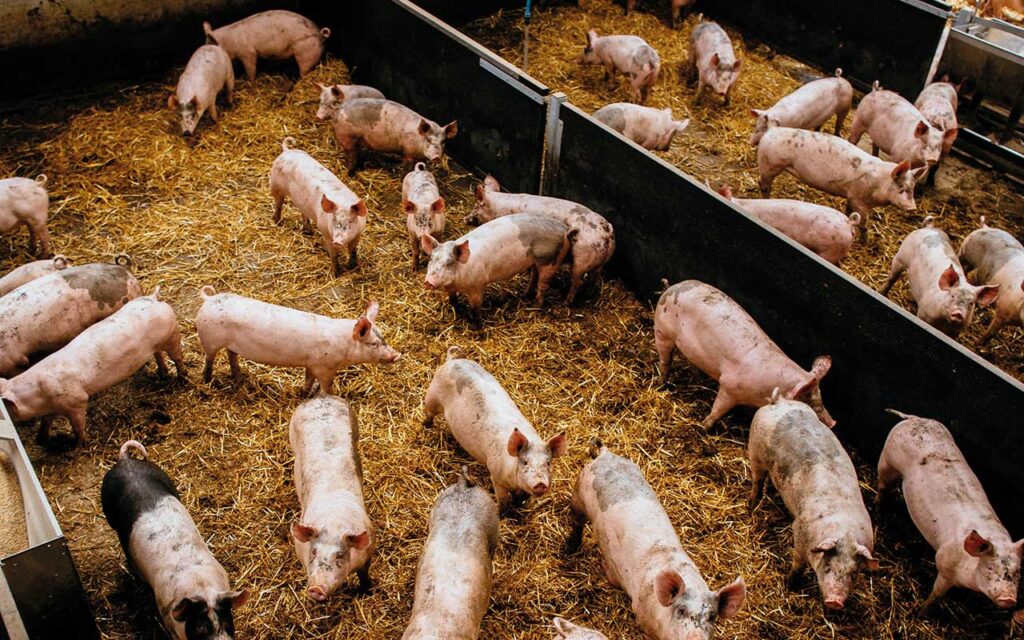

“We started as a traditional farrow-to-finish system, with a 1,600-sow herd rearing more than 40,000 pigs a year,” Hugh explained. “However, we decided to make the move to contract rearing five years ago, finishing up to 25,000 pigs a year for Karro Foods [now Sofina Foods], which ultimately supported the business through the extreme turbulence the industry has seen over the past few years.”

Hugh said his Nuffield scholarship in 2017-18 was the catalyst for this transformation. “My scholarship not only exposed me to precision farming technologies on pig farms across the world, but it also taught me we had to get out of breeding, as the economics weren’t there for us.

“I learned I had to make our business more resilient, and breeding pigs was holding that back, as the time from a gilt arriving on the farm to having pigs leave the farm is considerable, and much can change in that time.”

Faced with facilities that would require investment, alongside staffing shortages and herd health challenges, Hugh pushed forward with the changes.

Four years ago, a new shed was built, providing a straw-based facility for rearing and finishing pigs to RSPCA Assured standards, increasing pig finishing places from 1,000 to 2,500.

This expansion came at a significant cost of £150 per pig place, supported by funding from Lloyds Banking Group.

A focus on feed

During this period, the farm expanded into feed milling (mash and meal), processing 3,000t of feed a month using grain grown on farm.

This approach not only supports the pig operation by providing essential dietary components such as cereals, maize and home-grown beans for protein, but also supplies third-party companies, reducing food miles and emissions associated with feed production.

Supporting farmers through the transition

Lloyds Banking Group is calling on the UK government to standardise farm environmental impact measurement, deliver a decarbonisation strategy and unlock green finance to the sector.

As UK farmers face some of the most challenging times in agriculture’s history, the bank is supporting farms across all sectors to secure financial and environmental gains through tailored support, data-driven tools and access to green finance opportunities.

By funding over 80% of the farms that have taken part in the Soil Association Exchange assessment, Lloyds has, for the first time, developed a baseline for the ongoing measurement of on-farm environmental improvements.

To further its support for farmers through the transition, the bank is expected to announce a new funding pilot later this year, based on a private sector pooled-finance model.

This will aim to provide sustained payments to farmers adopting sustainable practices.

The findings and recommendations from the assessments can be found in two reports, Grounded in Evidence and From Data to Decisions, available online now at the Lloyds Bank website and Soil Association Exchange website..

According to research in 2020 at Aberystwyth University, funded by Farming Connect, more than half (50-70%) of greenhouse gas (GHG) emissions in pig production come from feed production, which is often overlooked in GHG analyses.

By producing its own feed, Shedden Farms has reduced reliance on imported soya without sacrificing pig performance.

“We were making big decisions to support the success of our business, but also its environmental impact,” said Hugh.

“Optimising feed conversion efficiency is crucial to not only maximise productivity, but also to limit emissions, which was a priority for us. We installed a liquid feeding system for pigs aged eight to 10 weeks through to finishing, to further reduce our soya dependence.

“This system converts human food waste into a highly nutritious, carbon-negative feed for pigs, as the emissions are already accounted for in the human food chain. The feed includes whey and wheat distillers’ syrup, alongside our home-grown ingredients.”

This feeding strategy enhances the pigs’ genetic potential by maximising growth rates, thereby cutting emissions as pigs spend less time on farm.

Pigs leave the farm at 24 weeks, weighing 118-122kg liveweight, with an average daily gain of 825-850g.

Farm facts

- Contract rears and finishes up to 25,000 pigs a year for Sofina Foods, some on straw, RSPCA accredited

- Farms 1,550ha of combinable crops, including wheat, barley, rape, oats and beans

- 250kW ground-mounted solar panels

- Increased straw-based pig finishing spaces from 1,000 to 2,500 by building another shed costing £150 per pig place, financed by Lloyds Banking Group

- Uses precision technology to maximise pig performance and welfare

- Grows own feed and uses liquid co-products, which is helping cut emissions

Linking sustainability and profitability

Farm data collected and analysed by independent consultants allow for continuous fine-tuning, ensuring pigs are raised as efficiently as possible, benefiting both the farm’s bottom line and the environment.

To further enhance pig production, the farm installed a high-tech ventilation system from Big Dutchman that adjusts temperature and airspeed according to the pigs’ growth stage.

This system has significantly improved air quality, boosting health and growth rates while reducing aggressive behaviour.

“You can’t have sustainability without profitability. That’s why we focus on feed, and have brought production in-house, monitoring pig performance and financials, and benchmarking against other producers to assess our progress,” Hugh added.

“We now have much more control than we did five years ago and face less risk, as we keep animals on farm for a shorter period.”

Environmental baseline

Hugh’s focus on sustainability was strengthened by participating in an environmental baseline assessment through Soil Association Exchange.

The service, funded by Lloyds Banking Group, helps farmers by delivering holistic surveys, evaluating six key areas – soil, water, biodiversity, carbon, animal welfare and social impact – and providing advice and strategies for improvement.

The data collected across all farms included soil sample analyses, hedgerow assessments and bird surveys, along with a comprehensive questionnaire to understand the farm’s operations.

Shedden Farms scored well on soil structure in terms of bulk density, pH and visual evaluation of soil structure, in addition to water use and carbon balance.

This is due to the high nitrogen input from the pig slurry and manure, which are effectively used across 1,550ha of the farm’s arable land, reducing reliance on artificial fertilisers.

A recent investment in precision slurry application equipment, including a dribble bar and flow analysis technology, has further refined slurry application.

“We conduct regular soil testing to ensure proper nutrition is applied to optimise crop yields,” Hugh explained. “This autumn, we’ll be developing an in-depth soil management plan to further improve our soil health.”

Recommendations from the assessment include introducing herbal leys to increase soil organic matter and installing rainwater harvesting to further improve water utilisation.

Both of these practices are available for funding via the Sustainable Farming Incentive (SFI) at £382/ha for herbal leys and Countryside Stewardship at £73/cu m for rainwater harvesting.

The farm already participates in two environmental agreement schemes – the Mid-Tier Scheme and SFI – which have led to the establishment of wildflower corridors, planting and managing hedgerows, and growing winter bird food and nectar flower mixes.

These initiatives will continue to develop through these schemes and recommendations from the assessment.

However, any changes implemented must benefit the farm, Hugh stressed.

“The next steps will be to work through exactly how to introduce the recommendations in the assessment and further reduce our environmental impact. The economics must stack up, but by maximising production and fine-tuning what we do, the two often go hand in hand,” he said.