With supplies of zinc oxide available at medicinal levels in piglet diets expected to be used up soon, AHDB has published the results of a comprehensive and rigorous review of the alternatives available to farmers.

The rapid evidence assessment (REA) was commissioned by AHDB and carried out in conjunction with Scotland’s Rural College (SRUC) and the Pig Veterinary Society. Zinc oxide (ZnO) is commonly used to reduce diarrhoea in post-weaned pigs. However, the UK pig sector is now in a transition period after EU regulations stopped the production of ZnO for therapeutic use, banning new marketing authorisations from June 2022.

The UK Veterinary Medicines agreed last year that any product within the supply chain at that date could used until its licence expires, but remaining product is expected to be exhausted by the summer. The industry will, therefore, need to adapt to managing post-weaning diarrhoea (PWD) without it, something some producers, vets and nutritionists have already been exploring, with mixed results.

Highlighting the research and the outputs available via the AHDB website, Dr Bethan John, AHDB animal health and welfare scientist, said: “A variety of potential alternatives are out there. The aim of the research was to make sense of them and establish what might work in each unique situation.”

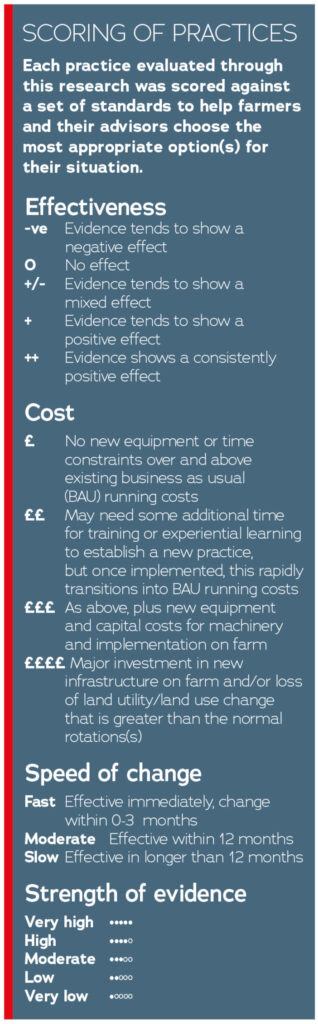

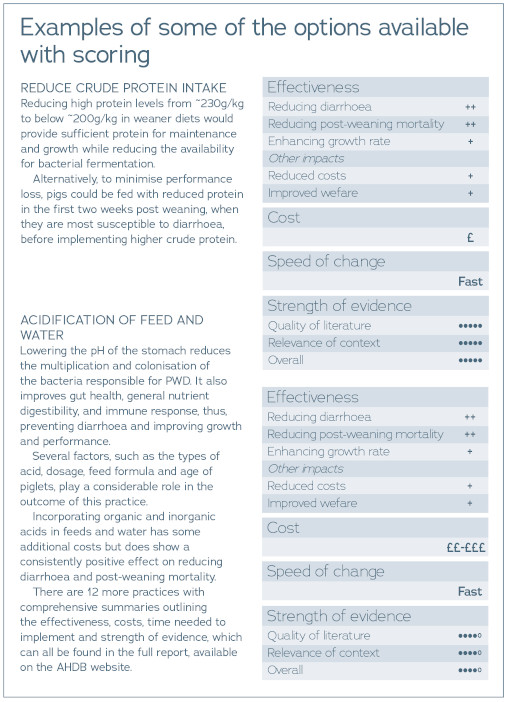

AHDB’s study assesses how alternative practices impact levels of PWD, post-weaning mortality and growth rate. It also scores each practice against effectiveness, cost, speed of change and strength of evidence to help producers and their advisors make informed decisions.

Dr John said: “This work provides a useful tool for the industry to navigate the loss of zinc oxide. The summaries will guide producers, alongside their vets and nutritionists, on which alternative practices might be most appropriate for their system and circumstances.

“A really exciting outcome was the development of a return-on-investment (ROI) calculator. This can be used to help determine which practices would work best for producers on their own farms.”

Unsurprisingly, there is no single intervention that scores as highly on repeatability or reliability as the use of ZnO at therapeutic levels to control PWD. This highlights the need for a multifactorial approach tailored to each farm, where all parties are involved.

What are the alternatives to ZnO?

The project was run under the Evidence for Farming Initiative (EFI), which was developed to improve agricultural performance by providing farmers, growers and their advisers with easy access to the best available evidence about effective and cost-effective practices.

The project was run under the Evidence for Farming Initiative (EFI), which was developed to improve agricultural performance by providing farmers, growers and their advisers with easy access to the best available evidence about effective and cost-effective practices.

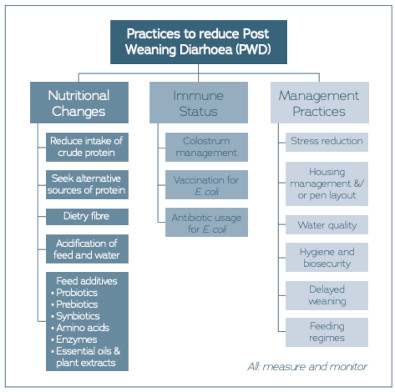

In 2022, researchers from SRUC screened and evaluated more than 100 scientific papers and articles addressing practices that have the potential to reduce PWD in pigs. Fourteen practices were identified and grouped into three categories:

- Nutritional changes

- Management practices and

- Altering immune status.

Nutritional changes

On the face of it, nutritional changes may represent the most straightforward alternative to ZnO. However, using these practices in isolation might not be sufficient to minimise risk factors for PWD. Commercial feed companies have been trialling products and generating a lot of data on the use of diets and feed additives as alternatives to using ZnO. However, most of these data are commercially sensitive.

Given these sensitivities and the details associated with feed prices, it was not practical to estimate returns on investments for most feed-related practices. However, where possible, a list of cost considerations was prepared.

If diets are home milled, there are a few more factors to bear in mind. Generally, there will be more flexibility to choose cheaper feed ingredients and formulate new diets, but the mill is likely to be the limiting factor in terms of adding extra ingredients. For any changes to feed formulations, it is essential that the farm’s vet and nutritionist are consulted.

Management and immunological practices

Management practices can be complex to implement but have the potential to prevent other diseases in addition to PWD, further improving piglet survival and increasing growth rates. Selecting the most appropriate practice(s) to implement would depend on the most significant factor causing PWD – taking into account nutritional vs infectious, or both– on each farm.

Immune status improvements, including colostrum management, are very effective in preventing PWD caused by pathogenic E. coli, but can be costly to implement. Other practices, such as phage therapy and genetic selection, have good prospects as alternatives for ZnO, albeit they are not yet commercially available.

The management practices reviewed in this research are rarely implemented as single measures but rather as a group of measures or interventions that will inevitably encompass a greater effect.

Return on investment

The development of an ROI calculator means producers can sit down with their vet and nutritionist and look at the summaries of the different practices and determine which ones would work best for them on their farm.

Many factors need to be considered as part of the calculation, and it will be farm-specific, dependent on the initial layout and practices of the farm and whether the practice changes the cost structure of the farm.

Time is running out

While ZnO might still be present in many weaner diets, stocks will not last beyond the summer. As a producer, if you have not yet begun to have discussions with your vet and nutritionist, now is the time to do so. If you have had conversations, ensure measures are put in place promptly to reduce the likelihood of PWD come summer.

Dr Charlotte Evans, AHDB Head of Engagement (Pork), said: “Even though economics are challenging at the moment, the earlier action plans are put in place, the better because we will have to remove it [ZnO] eventually, and there is concern among the industry that it might go quite quickly.

“We need to be prepared, and with all of these practices, it will take time to embed them into routines, so the sooner we start, the better prepared we will be to manage without ZnO.”

Management practices seem to be the most effective when compared with nutritional changes and immune status in controlling PWD.

Management practices seem to be the most effective when compared with nutritional changes and immune status in controlling PWD.

However, identifying the most important risk factors contributing to disease on each farm is essential before implementing practices to control it.

Management will differ considerably between farms, and most of the practices discussed in the report overlap. For instance, stress reduction as a practice encompasses changes in different areas, such as nutrition, environment, feeding and management practices.

One of the most important messages is that in all cases, though especially in the case of management practices, it is likely that applying more than one practice at once has an additive effect. This means that implementing a range of measures tailored to the problems of each farm is probably the best solution to control PWD.

Dr Morris added: “We know that with nutrition and management practices, if we get better performance and better general health as a result, then that might well pay for itself. But once we get to the point where we’re adding in antibiotics or using vaccinations, we know those are more expensive than zinc.”

High feed costs and the losses seen across the UK pig sector over the last year leave a tight or non-existent margin for farm structural changes or for any increased costs. However, changes that have the potential to stabilise the farm in terms of disease and improve efficiency may present excellent returns when inputted into the ROI calculator.

This could be a good time to perform an internal audit to systematically assess all farm operations to identify areas and processes that can be improved. After this, a list of the most cost-effective actions could be prepared.

Find out more

- AHDB has produced a podcast about this research by listening featuring Bethan John, Charlotte Evans and Jim Morris.

- Visit the AHDB website to download the full set of practices and access the ROI calculator: ahdb.org.uk

- AHDB published guidelines on coping without zinc oxide.