British pig farmers have saved themselves an estimated £15.3m in environmental mitigation costs thanks to significant progress in reducing ammonia emissions.

It is quite the bold statement and a very satisfying one for all concerned, given that the work only came to light following AHDB’s multi-year ammonia monitoring trial, AHDB projects and engagements relationships manager (pork) Zanita Markham explained.

The findings and recommendations have now been incorporated into the Environment Agency’s (EA) updated ammonia emission factors, which could also help with future planning applications, to bring this project to a satisfying conclusion.

The studies began after international agreements on air pollution were put in place, meaning the UK farming industry is required to achieve a 16% reduction in ammonia emissions by 2030, compared with 2005 levels.

“The target formed part of the government’s Clean Air Strategy and while it has not changed, there was significant concern over the initial standard emission factors [EF] being used by the EA to make calculations within the pork sector.

“They felt outdated, as has proven to be the case, given that they were based on studies over 20 years old,” Ms Markham explained.

“Approximately £250,000 of levy funds were pumped in to kickstart the project, which developed a more accurate suite of EFs.

“This means costs – such as new buildings, dietary changes or slurry treatment technologies – that would otherwise have been needed to keep producers compliant are no longer required, as we are on our way to meeting the 2030 target.”

Reduction targets

Ammonia is released to the atmosphere from slurries and nitrogen fertilisers. Housing, handling, storage and spreading of slurry all contribute to the spread of any pollution.

When the gas reacts with other compounds it forms secondary particulate matter, which can affect human health. It also contributes to smog in urban areas, as well as causing damage to sensitive habitats such as lakes, heaths and woodlands.

According to Defra’s Code of Good Agricultural Practice for Reducing Ammonia Emissions, agriculture is responsible for around 88% of the UK’s total emissions. And in the same government department’s 2015 report on ammonia emissions from UK agriculture, the pork sector accounted for 8% of the total.

The Environmental Permitting Regulations (EPR) require all pig units with more than 2,000 pigs above 30kg, or more than 750 sows, to have an environmental permit and all permitted producers must meet the best available technique (BAT) associated emission levels (AELs) – which are benchmark levels for farms to achieve.

A new set of BAT conclusions, published in 2017, included limits on emission levels for ammonia, nitrogen and phosphorus.

“This means that permitted farms must ensure emissions do not exceed the stated levels, and are required to adopt minimum standards of management practice and BATs – for example, altering the protein content of the feed, building type and design, slurry storage and management systems,” Ms Markham added.

Demonstrating pig housing emissions

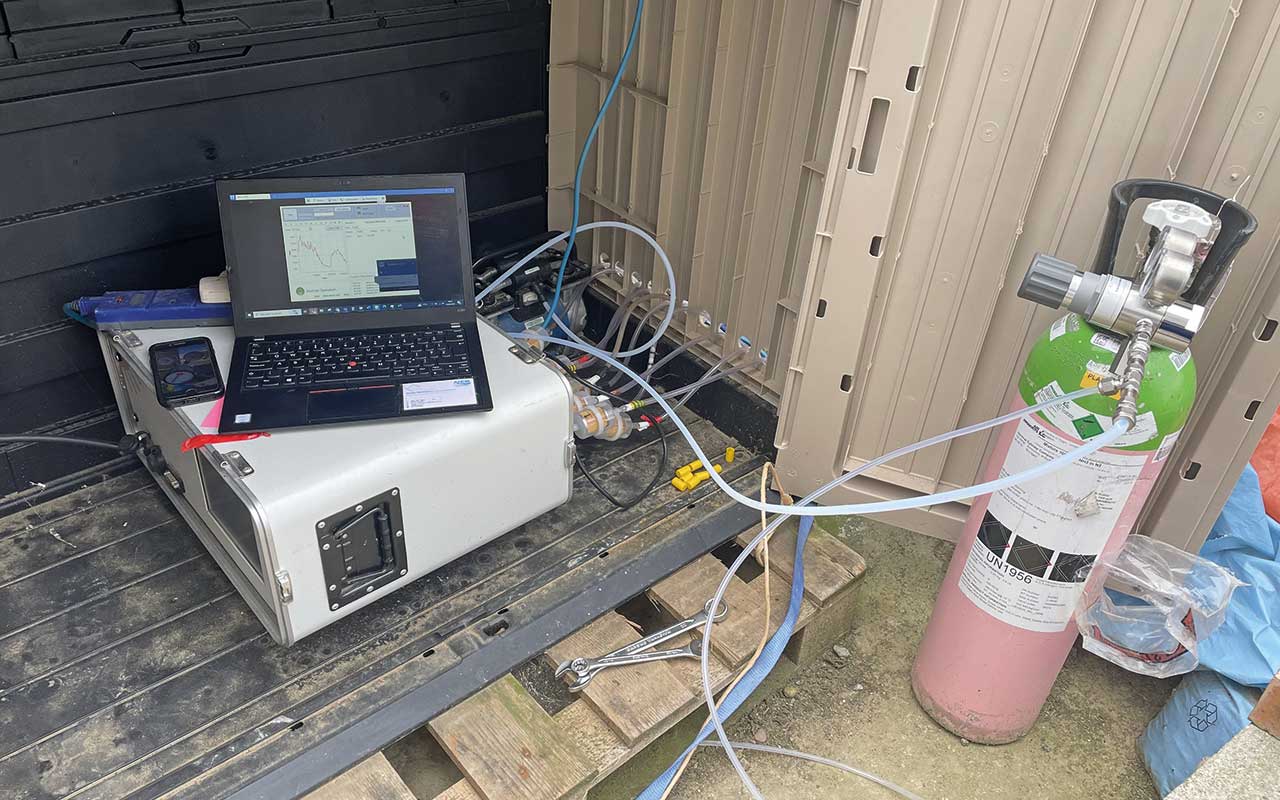

Having taken up the baton from a former colleague, Nigel Penlington, Ms Markham managed AHDB’s intensive study from start to completion.

“It was clear that by using the older EFs, UK pig farms were not going to reach compliance to the BAT AELs,” she said. “But the project provided updated data on the performance of different types of modern pig housing and evidence to support revising the ammonia emission factors for UK pig housing.”

The Pork Sector Council called for AHDB to take the lead and conduct more studies in the area.

The initial outlay of levy investment was needed as there was little qualifying information to help relate EF to commercial performance, because the techniques previously used were limited and measurements followed no common protocol.

Importantly, AHDB’s ammonia monitoring, together with all other evidence, has demonstrated that a lot of existing pig housing is already compliant, therefore avoiding unnecessary expense for those producers.

“The data we gathered show emissions on pig farms today are generally much lower, and in some cases have halved. With the changes to EFs, most units are already compliant with the new target emissions levels,” Ms Markham added. “For example, factors for finishers on straw are now an average of 1.88kg of ammonia per animal place per year compared with the outdated figure of 2.97kg.”

New standard emission factors (EF) |

|||

| Figures showing in kg NH3/animal place/year |

Previous EA EF (2013) | New EA EF (2024) | Relative change |

| Pigs from 7-30kg | |||

| Fully slatted floor | 0.94 | 0.443 | -52.87% |

| Fully slatted floor – frequent slurry removal (minimum of weekly) | 0.70 | 0.332 | -52.57% |

| Solid floor, straw system | 0.675 | 0.254 | -62.37% |

| Pigs over 30kg (fully slatted floor) | |||

| Fully slatted floor | 4.14 | 2.81 | -32.05% |

| Fully slatted floor – frequent slurry removal (minimum of weekly) | 3.11 | 2.11 | -32.15% |

| Solid floor, straw system | 2.97 | 1.888 | -36.43% |

| Farrowing | |||

| Fully slatted floor | 5.84 | 4.62 | -20.89% |

| Solid floor, straw system | 8.88 | 5.41 | -39.08% |

| Dry sows (includes gilts) | |||

| Fully slatted floor | 3.01 | 2.94 | -2.33% |

| Fully slatted floor – frequent slurry removal (minimum of weekly) | 2.26 | 2.21 | -2.21% |

| Solid floor, straw system | 4.57 | 3.29 | -28.01% |

What the results mean

By the end of the year, the EA is due to publish the new set of standard EFs on its website, with most systems comfortably under the BAT AELs.

The EA, which is responsible for enforcing EPR in England, uses EFs to assess the effect of permitted farms’ ammonia emissions on the environment, both during the permit application process and as part of annual pollution inventory reporting.

Natural England also uses them in ammonia dispersion modelling as part of planning applications, while Defra uses them to estimate UK emissions of ammonia from pig production for annual reporting to the European Commission.

For the pig sector, ammonia reductions of approximately 30% for finishers and 50% for weaners have been demonstrated, reflecting the great strides that producers have achieved already, Ms Markham said.

“We have seen the reduction of emissions from the industry by improving production efficiencies, feed, housing and slurry management,” she said.

“This should save the industry more than £15m in estimated operation alterations and ammonia mitigation and abatement techniques based on prices from 2017, when the study was done – of course, this saving will have grown considerably now.”

The bulk of these costs come from finishing accommodation. However, two systems remain non-compliant with the BAT AELs – pigs over 30kg and dry sows, both on fully slatted floor systems.

“But it may be possible to reduce emissions by 8% and 9%, respectively, by altering the protein content of the feed and reviewing building design, in addition to slurry storage and management systems,” Ms Markham advised. “Or, if the applicant wishes, to self-evidence a site-specific emission factor at the permitting stage.”

The EA will communicate with operators who have applications in the process of being determined for these systems, if they fall into the minority of cases where the new emission factors are increasing.

Outlook

Ms Markham concluded: “This new baseline demonstrates how far the sector has come in reducing ammonia emissions.

“Further innovation and investment, particularly in building design and management techniques, could improve the picture even more. Using levy funds to prove the responsibility of the sector now and in the future in this way is helping to inform both policymakers and consumers.”