It’s often said that the pig sector has a lot to learn from those involved in poultry production, and one area where this is particularly true is with regard to water quality. Indoor broiler rearing is done on a scale and to a standard that pig producers would find hard to match, and part of that is removing as much variability from the system as possible. The genetics, feed and environment are all closely controlled, and the same goes for the water supply.

We tend to take water for granted, especially if we get it from a mains supply in a domestic setting, but when it comes to livestock production it’s a factor that just can’t be ignored. It’s been found that maximum food intakes are dependent on sufficient water of a suitable quality being readily available. In the first instance this means an absence of odour or taints that might limit intakes, but just as important is the absence of bacteria that could actually introduce disease into the animals.

It’s already well known that water from boreholes can be contaminated and require treatment before being offered to stock, but it’s also important to recognise that even if the farm’s water comes from the mains, it isn’t necessarily clean when it reaches the drinkers. Organic matter known as biofilm can build up in the pipes, and this can provide the perfect breeding ground for bacteria that has the potential to affect production.

Poultry and pigs

Jonathan Peake of Nottinghamshire-based FS Peake & Son is well placed to understand the importance of clean water for livestock systems. His business has broiler sheds and bed-and-breakfast pigs (reared under contract for AQM), and the water supplied to both species is treated with Xziox, manufactured by Essex-based Ximax Environmental Solutions and now distributed to the UK pig sector by AQM.

Mr Peake has been using the system for his broilers for about three years now, and then extended it to the pigs about 12 months ago. Water for both enterprises is supplied from a borehole, and all that was required to provide treated water to the pigs was the addition of a second dosing pump in the pumping shed as both systems share the same 300-litre tank for the Xziox solution.

The FS Peake & Son pig shed has room for 1,100 weaners on an all-in/all-out system, and this allowed the water lines to be treated with a higher initial dose of Xziox when there were no pigs on the farm. This involved setting the pump to provide a high concentration of the active ingredient to kick-start the process and tackle biofilm and any other microbiological material in the pipes. Although not absolutely necessary, this approach is recommended as the treatment can loosen biofilm to the extent that the drinking lines can become blocked. Treating with an initial high concentration and then removing the drinkers and flushing the system can reduce the chances of that happening.

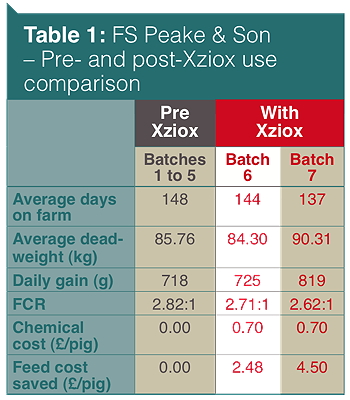

The FS Peake & Son pig manager Douglas Goddard has been monitoring the effects of the treatment (see Table 1) and saw immediate positive results. Compared with the five batches through the shed before treatment with Xziox started, the first pigs produced with the treated water were on the unit for four days less.

Better FCR

And although the average deadweight at slaughter was a bit less, the average daily gain was higher and the FCR was better. Based on a feed cost of £62.39/pig, the FCR improvement was calculated as being worth £2.48/pig for a cost of 70p/pig in chemical costs.

And the improvement was even greater with the seventh batch through the shed, with the FCR showing a 0.2 improvement increasing the savings in feed costs to £4.50. More impressive, perhaps, was a the fall in the average time of the pigs on the farm from 148 days pre-treatment to just 137 days, and a huge increase in the growth rate from 718g to 819g/day.

Similar results have been seen in other herds too, where the benefits have included reduced antibiotics use and associated lower mortality. Douglas Goddard says that even though scours have never been much of an issue on the Nottinghamshire farm, they’re completely absent now. Incidentally, unlike acid-based water treatment systems, Xziox-treated water is completely compatible with water-delivered antibiotics. Treatment can begin straight away and, as the biocide treatment continues, there’s no risk of the pigs being exposed to contaminated water when their health has already been compromised.

The Xziox system costs about £1,500 to install, with the set-up including a tank for the chlorine dioxide, the electronic dosing pump and an electronic flow meter. The chemicals to make up the biocide are supplied under contract and the cost – which averages 70p/pig – includes maintenance and repairs of the system.

Xziox water treatment

Xziox is described by Ximax Environmental as a stable biocide that eliminates bacteria, disinfects surfaces, breaks down biofilm and is also effective for odour control in water.

Originally developed for the oil and gas industries, Imax’s patented water treatment is delivered to customers as two inert ingredients that are mixed and diluted with water (in a ratio of 0.05:0.05:0.90 respectfully) to create a chlorine dioxide solution that retains its active properties for four to six weeks. This is then added to the water supply at the ideal rate to provide clean and safe water for the application at hand.

Now used around the world, Xziox water treatment systems can be found in situations as diverse as hospitals and food-processing plants, while agricultural uses include poultry and pig production as well as large-scale irrigation systems for soft fruit and vegetable production, where it’s capable of treating water at flow rates of 600 cubic metres an hour.

The dosage rate will be different for every application and is established by carrying out an independent laboratory analysis of the water to be treated. Xziox works by killing bacteria, viruses and other microbiological agents by penetrating the cell wall and deactivating them.

Microbiological profile

The aim is to closely match the Xziox dose to the microbiological profile of the water supply so that only a small amount of the active ingredient is left by the time it has done its job and reaches the livestock (less than 0.5 parts a million is the target). This isn’t because of any danger the product poses to pigs or poultry – or indeed farm staff – but simply the fact that it’s more cost-effective to optimise the dosage rate.

As the water pipes tend to become cleaner over time with the use of Xziox, regular samples are taken so that the dosage rate can be adjusted, keeping treatment costs to a minimum.

It should be noted that Xziox doesn’t leave any harmful residues in the water supply as it works. It simply breaks down into sodium chloride (table salt) and oxygen. It is also pH neutral and won’t corrode pipework, fittings, water tanks or drinker lines.