Due to PRRS and PEDv, there’s been a lot of talk recently about biosecurity and sanitation. Rightly so. In all the plethora of words and print, two areas of sanitation (biosecurity is about keeping disease out while sanitation is keeping it under control) seem to have been undervalued and under-discussed.

What about farrowing pen floors?

The first is not cleaning under slats/perforated floors in the farrowing pen. Either sufficiently or not at all. This has always worried me. Just imagine – human babies being delivered over the hospital`s sewage pit! The mind boggles – utterly ridiculous. But this is what we do, or have to do with baby pigs. I see it every day, the slatted undersides difficult and sometimes impossible to reach with a lance through a hatch and few – very few – beds with a hinged or lift-away facility ensuring as thorough a clean as for the more accessible surfaces in the farrowing pen.

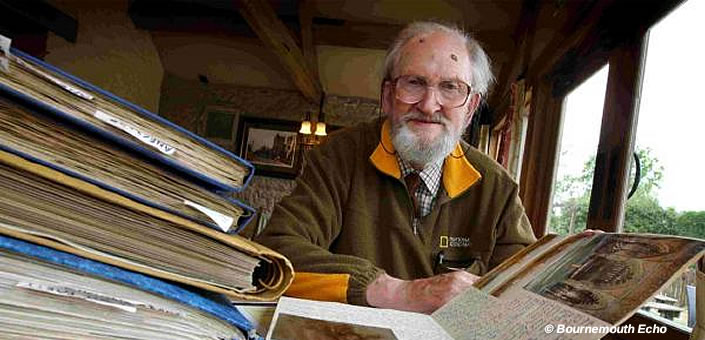

Years ago Terry Heard, our pig vet at Dean’s Grove farm, did some bacterial swabs and showed us the horrendous levels of bacteria in the petri dishes from below the slats after our so-called all-in/all-out sanitation of our farrowing pens, which we thought was pretty good. From these results, it couldn’t have been, so we inserted a liftable grill in each bed and made sure the whole undersurface got a good clean when we came to all-in/all-out time, which pleased Terry.

Better results?

Were the results that much better? Less scour incidence and better growth to weaning? We couldn’t really tell as this was up and down all the time. Subsequently, I’ve not found any before-and-after figures in the literature either, and I feel someone should try to do this; the disinfectant suppliers, for example.

I’ve written to two and they thought it wouldn’t make much difference, but when I asked whether they had taken the under-slat swabs as we did, I got no reply. So there’s a bit of research waiting to be done. By the way, the cost of remodelling with access grilles raised our cost of production by 2.4% spread across three years. I had to record this as management grumbled about the expense – as management does!

Bulk bins

The second modification to existing or new equipment concerns the sanitation of food bulk bins, this time for mycotoxin build-up. Here I have before-and-after results, and what the cost of the solution is likely to be. But again not much enthusiasm from the bin manufacturers this time. The accumulation of “crud”, especially in the upper surfaces of a storage bin becomes full of mycotoxins.

Whether it has been scientifically proved that it affects performance through the food I’ve not so far discovered, but I’m quite sure it does. This was because years ago as a junior trouble-shooter for Boots the Chemists, which then had an agricultural arm, I was plagued by what I called in my ignorance “won`t go away diseases” that were brought under control by medicating the food, but continually came back again after a while. This pleased my employer, which sold the medication, but worried me sick as I could see my early reputation as a farm adviser going down the tube!

What worked

Another vet, this time Sigurd Garden in Scotland, told me to clean the insides of those bins. When it could be done, it worked a treat – the diseases went away and kept away. That was when it could be done, as to get in the top hatch was both difficult and dangerous and even tested my mountaineering nerve to the limit!

Since then, I have been at the bin manufacturers to put a foldaway bulkhead door into the side (as in a ship) so that a ladder can be inserted to make access safe and so much easier, but they don`t like the 15% or more extra cost that this would entail. Again, some decent research to prove the benefit and establish a cost-benefit ratio is needed.

I live in hope!