A new slurry separator that reduces contaminants, removes solids, and offers farmers a way to reduce the volume of stored slurry, has been made available to the UK through slurry specialists Tramspread.

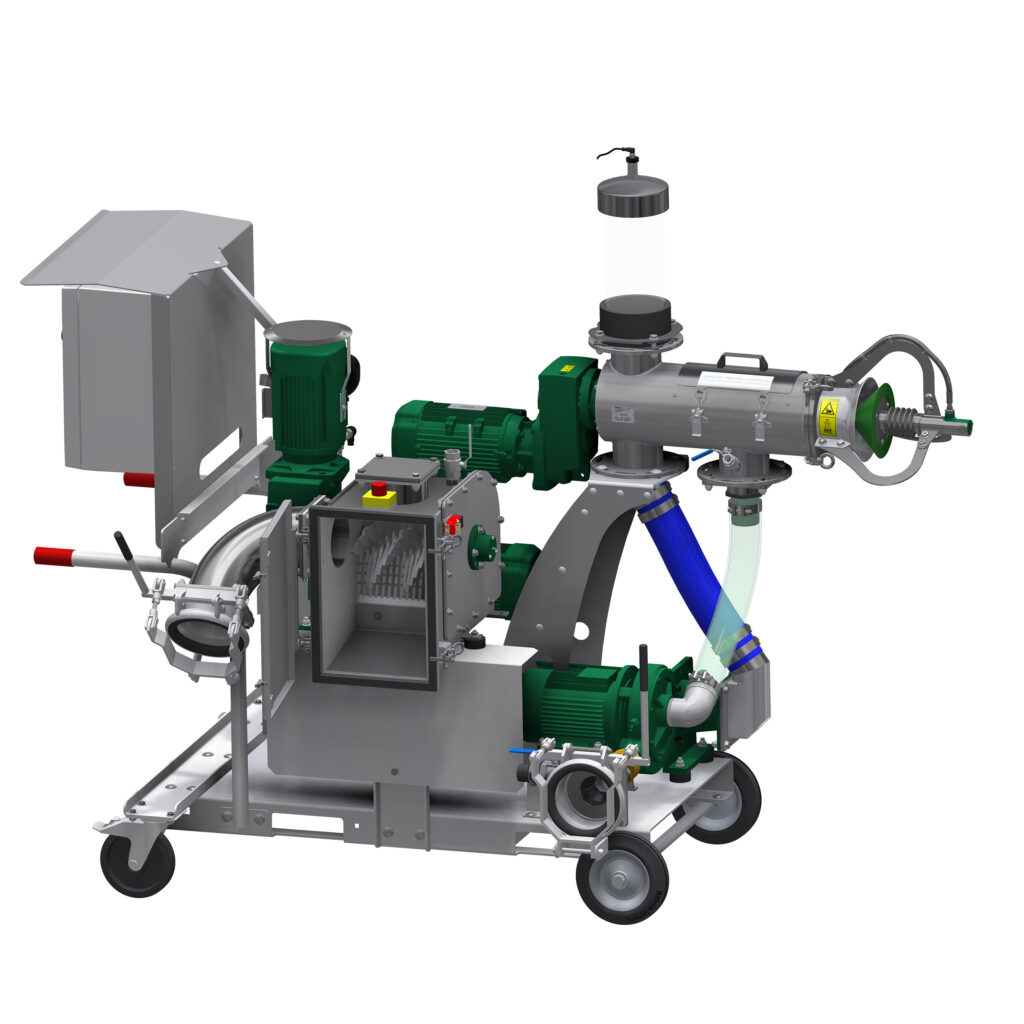

Stallkamp launched the PSS 2.2-400 ComPress at Agritechnica in 2019. The machine uses a screw pump to suck slurry through a contaminant filter. The filtered slurry is then transferred to a separator that extracts the dry matter leaving nutrient rich liquid.

Commenting on the product, John Tydeman from Tramspread said: “Storing slurry has been hard for many farmers this winter because rainfall has been so high. Separating is a cost-effective way to reduce the overall volume of slurry. It also creates a more manageable solid manure and a better quality liquid slurry that is easier to apply using dribble bars or a trailing shoe.

“The liquid only loses approximately 10 percent of its N, P and K value so is still a valuable input for grassland. It also benefits from the filtration process which removes potentially harmful impurities and helps grass to absorb the nutrients more efficiently.”

This new slurry separator will be able to help tackle recent government legislation which demands that all farmers have sufficient facilities to store slurry and poultry manure produced in a yard or building. This applies from 1 October to 1 April for pigs, and poultry and 1 October to 1 March for other farming operations. Slurry stores must also have the capacity to store all rainfall and any wash water that accumulate during these periods.

Tydeman added: “For farmers with fluctuating or increasing herd sizes, abiding by this legislation can be hard. However, a screw press offers a cost-effective way to manage slurry, prevents the immediate need for further storage and provides the best dry and liquid products for farm use.”